HOT PRODUCT

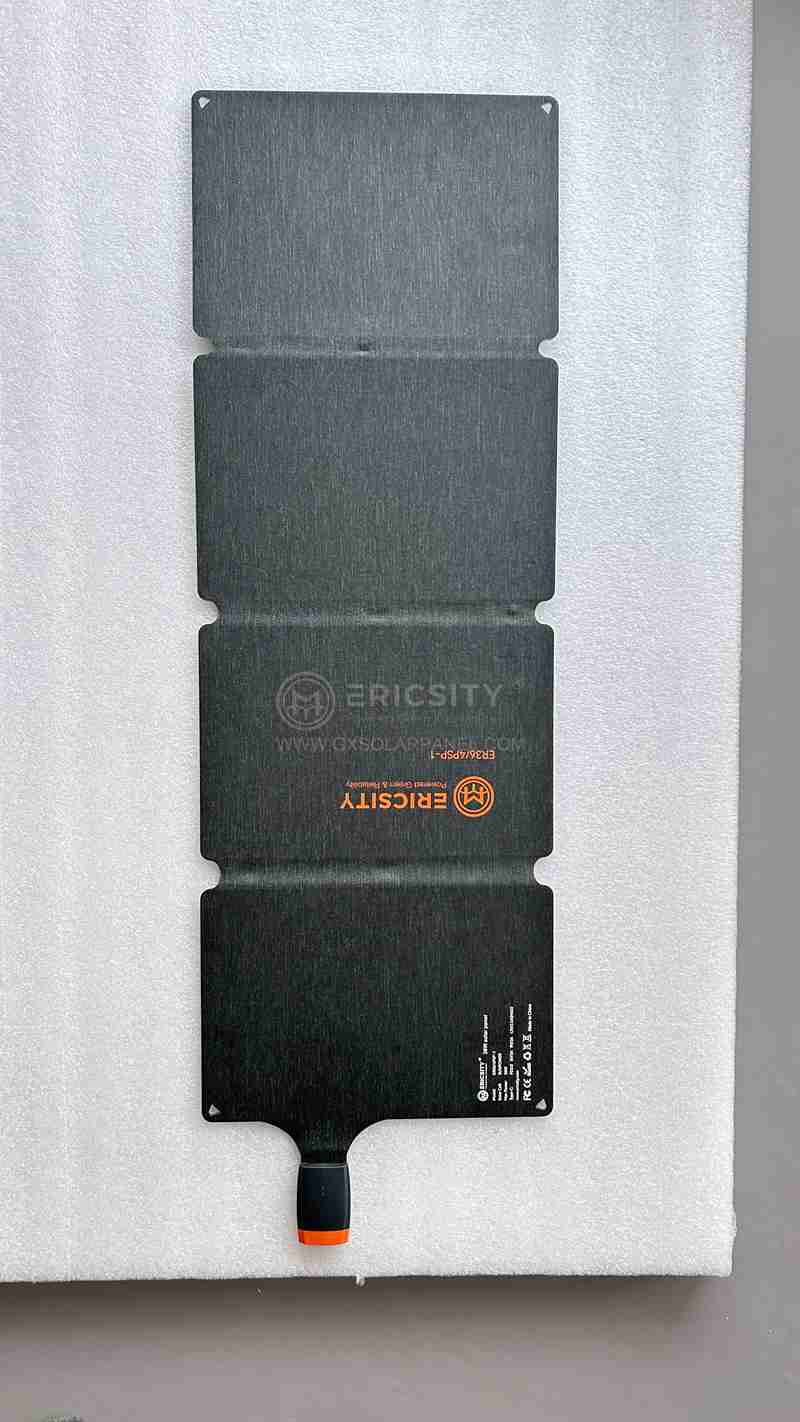

Product Details

Efficiency Meets Flexibility: A Guide To Mono Solar Panel Technology

Efficiency Meets Flexibility: A Guide to Mono Solar Panel Technology

As the demand for clean and renewable energy sources continues to grow, solar power has emerged as a viable solution. Solar panels, specifically mono solar panel technology, have gained significant popularity due to their efficiency and flexibility. In this article, we will delve into the world of mono solar panels, discussing their advantages, applications, and future prospects.

Mono solar panels, also known as monocrystalline panels, are made from a single crystal structure, typically silicon. The manufacturing process involves cutting the crystal ingots into thin wafers, which are then assembled to create the panels. This method results in a higher purity of silicon, leading to increased efficiency.

Efficiency is a crucial factor in solar panel technology, as it determines the amount of energy converted from sunlight. Mono solar panels have a higher efficiency rating compared to their counterparts, polycrystalline and thin-film panels. With efficiency levels reaching up to 22%, mono panels offer a greater power output per square meter of installation. This makes them ideal for applications with limited roof space or areas where maximum energy generation is desired.

Another advantage of mono solar panels is their ability to perform well in low-light conditions. The single crystal structure allows for better absorption of sunlight, ensuring continuous energy production even during cloudy or overcast days. This characteristic makes mono panels highly reliable in areas with varying weather conditions, ensuring a consistent energy supply.

In addition to efficiency, mono solar panels also excel in terms of durability and longevity. The single crystal structure provides enhanced resistance to temperature fluctuations, making them less prone to thermal stress and microcracks. This durability ensures a longer lifespan for the panels, reducing maintenance and replacement costs over time.

Furthermore, the manufacturing process of mono solar panels enables customization and flexibility. The wafer cutting technique allows for the creation of different shapes and sizes, providing design flexibility for various applications. This adaptability is particularly valuable in architectural integration, where solar panels can be seamlessly integrated into building façades, windows, and roof structures, enhancing the aesthetic appeal of the structure while generating clean energy.

The versatility of mono solar panels extends beyond architectural integration. They can be used in a wide range of applications, including residential, commercial, and utility-scale installations. Their higher efficiency makes them suitable for residential rooftops with limited space, where maximizing energy generation is essential. At the same time, their durability and customized designs make them attractive options for large-scale solar farms and commercial buildings.

The future of mono solar panel technology seems promising. Ongoing research and development efforts aim to improve efficiency even further and reduce manufacturing costs, making it more accessible for widespread adoption. Moreover, advancements in materials and manufacturing techniques may lead to the development of flexible mono solar panels, enabling their use in unconventional settings and enhancing their integration into various surfaces.

In conclusion, mono solar panels offer a compelling solution in the quest for clean and renewable energy. Their high efficiency, durability, and design flexibility make them an ideal choice for a wide range of applications. With ongoing advancements and innovations in this technology, we may see mono solar panels playing an increasingly significant role in meeting the world’s energy demands while reducing our carbon footprint.